No data

12

2022

-

10

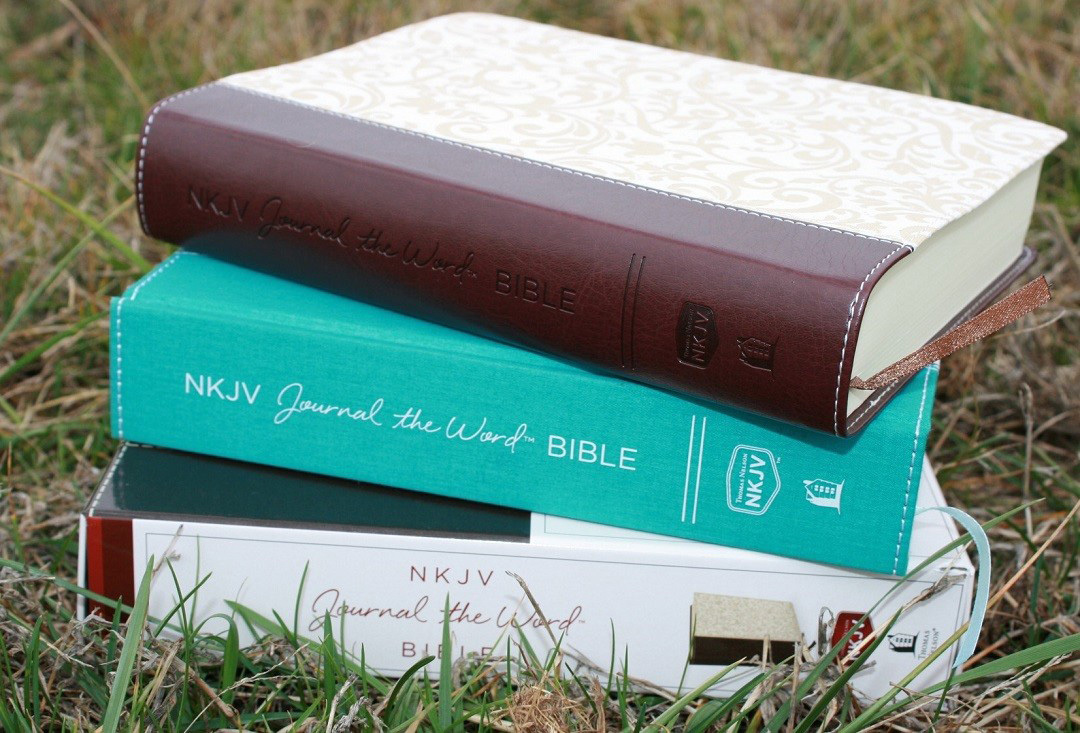

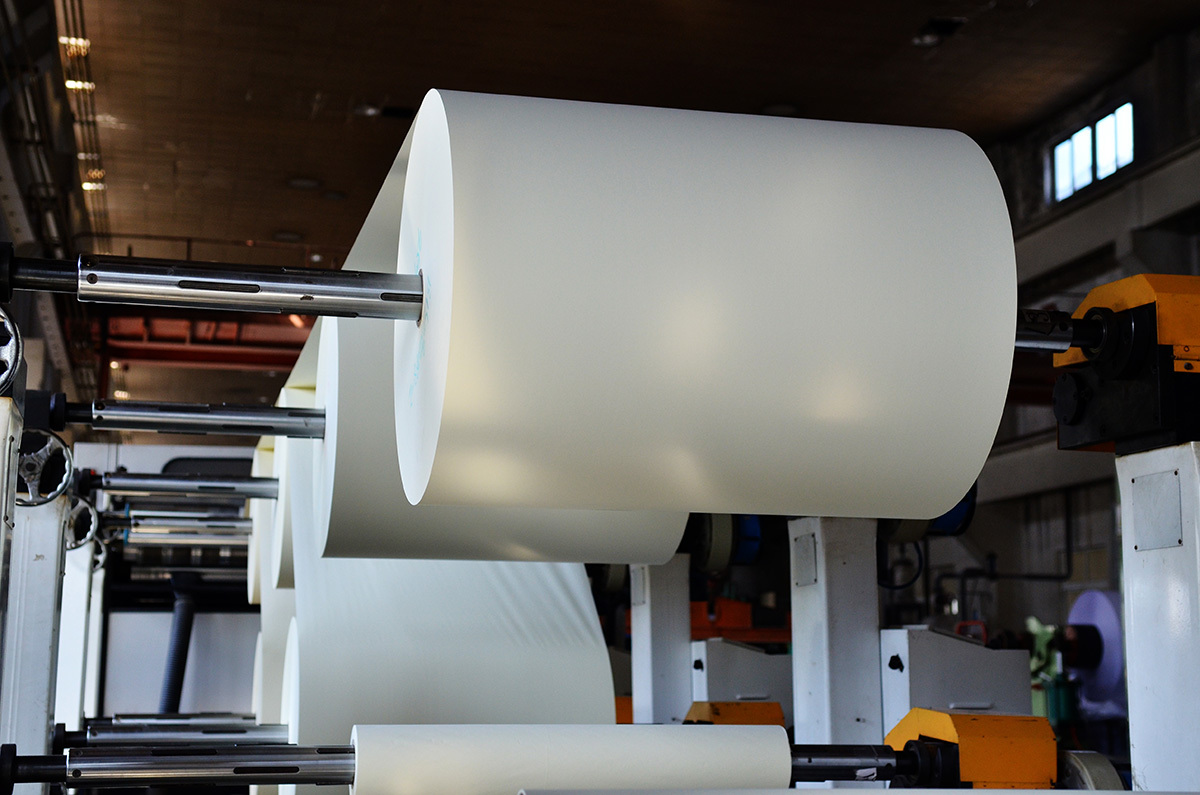

Meilin Paper Deeply Carries out Lean Benchmarking Management to Achieve Sustainable Development

Author:

Since 2022, Meilin has closely focused on the overall requirements of "managing losses and creating efficiency, transformation and upgrading", with the goal of improving quality and efficiency, comprehensively deepened the precise benchmarking management activities, and achieved the scientific and sustainable development of the enterprise.

First, do a good job in the study, exploration, research and application of new technologies. Aim at the development direction of new technologies in the industry to carry out application innovation and integrated innovation, so that mature new technologies can play a more and greater role in specific practical applications. By optimizing the production process of various paper grades, improving product quality, reducing production costs, optimizing and upgrading the product structure, highlighting the functional advantages, quality advantages and cost advantages of the product, the product quality can not be replaced and the cost advantages can not be copied.

The second is to give full play to the exemplary role of the "innovation studio" and let "five small innovations" blossom everywhere, so as to improve the technology and skills of the staff team and improve the overall quality of the staff team.

Third, implement lean benchmarking management to reduce costs and increase efficiency. The company carries out technological innovation around existing equipment to improve equipment performance year by year and ensure that it will not be eliminated in the rapidly changing equipment upgrading.

The fourth is to do a good job of personnel skills training. Since 2021, the company has cooperated with well-known human resource training companies in Beijing, and organized professional training for personnel at all levels every month. The training content covers business, safety, sales, etc., which has played an important role in improving the quality of all employees.

In addition, in order to do a good job in benchmarking lean management activities, the company also further optimized the design of the work assessment process and improved various unreasonable links in the production and operation process, which not only improved the production efficiency but also reduced the production cost.

Related news